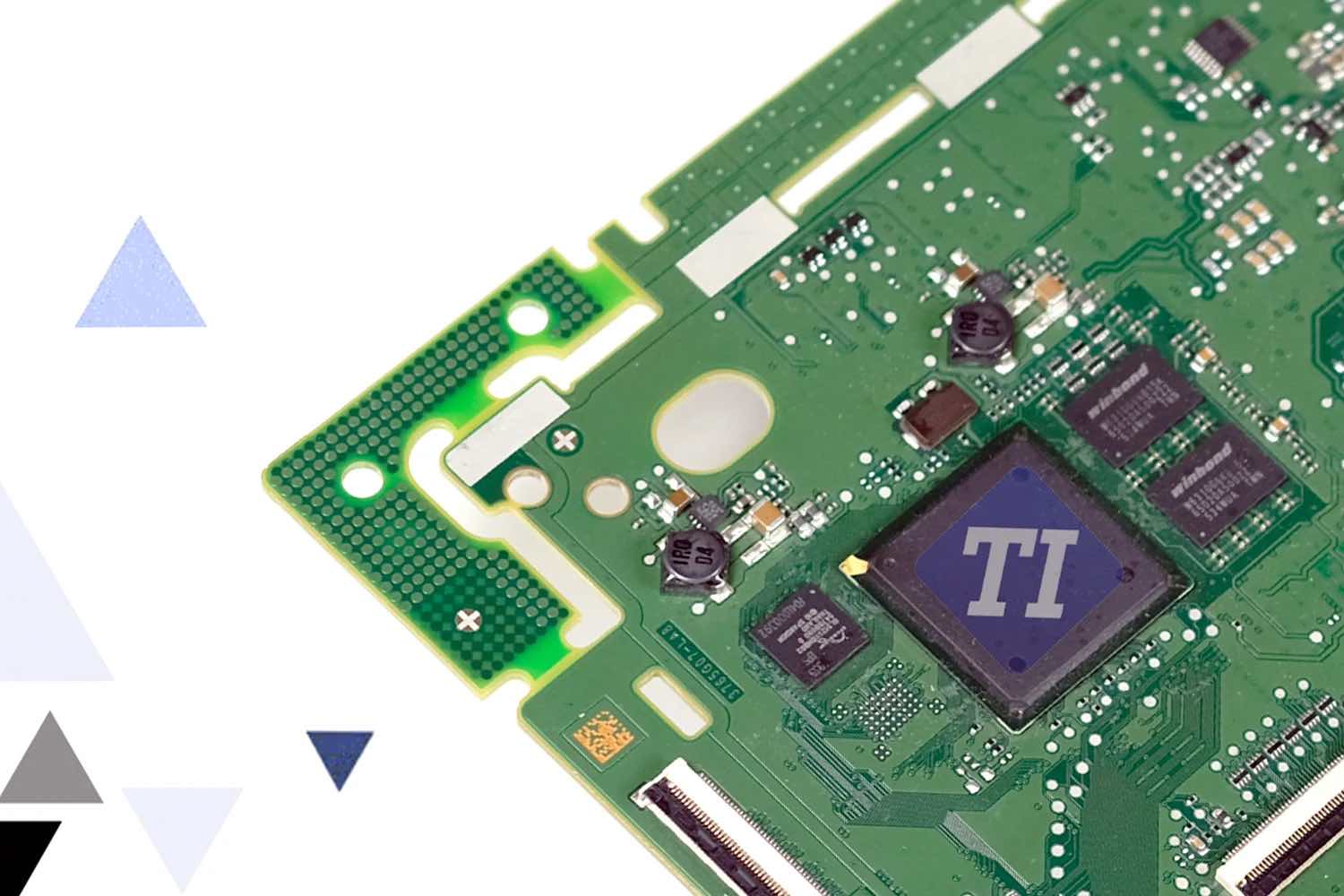

PCB Assembly - Electronic Printed Circuit Board Manufacturing

TI-Electronic – Knowledge-based electronic manufacturing

PCB Assembly services for printed circuit boards in Electronic Manufacturing

est.

1992

3 decade of expertise

98,6

%

Satisfied customers

At TI-Electronic, we specialize in the production of high-quality printed circuit boards (PCBs), offering a full range of services from prototype development to small, medium, and large-scale serial production. Our extensive experience and expertise in electronic assembly ensure that we deliver reliable and cost-effective solutions to our clients, meeting the demands of a fast-evolving electronics industry.

Our strategic location in Hungary allows us to provide fast and flexible delivery across the European Union, ensuring that your projects are completed on time and within budget. With continuous investments in cutting-edge technology and production capacity, we aim to provide long-term, high-quality service to meet your needs.

AUTOMATIC PCB Assembly

MANUAL PCB Assembly

Yamaha Pick & Place assembly lines

SMT panel assembly: from 01005 to 45mm x 45mm

Special components: BGA, µBGA, flip chips, CSP, connectors

THT installation: axial, radial and manual installation

Soldering: Lead-free and unique soldering techniques

Small – Medium – Large production volume option

With 30+ years of management experience

PCB varnishing for water resistance High IP standard level

High and low capacity soldering technologies

Extensive contacts in industry

High flexibility

HIGH TECH PRODUCTION AREA

Production supporting services

Complete ESD production areas

AIR Filtered Climate Systems

Climate tests and more

12,000 square meter production area

All testing options are available

Panel programming: Customized programming services

Experience in all standards and certification processes

Online technical customer service

TI-Electronic – Circuit Assembly Technologies:

TI-Electronic has been a trusted partner in electronics manufacturing for over 30 years, offering innovative PCB Assembly solutions to its customers. Our comprehensive services range from surface mount technology (SMT), through through-hole technology (THT), to BGA assembly and manual soldering.

💡 Why choose TI-Electronic?

✅ State-of-the-art production lines: Yamaha Pick & Place, precision soldering technologies

✅ Quality assurance: AOI, X-ray inspection, functional testing

✅ Customized solutions: From prototype to series production

✅ Flexibility and fast delivery: With competitive lead times throughout Europe

SMT – High Precision Surface Mount Technology at TI-Electronic:

Surface Mount Technology (SMT) is one of the most advanced PCB assembly processes, in which electronic components are mounted directly on the surface of printed circuit boards (PCBs). This enables higher component density, faster manufacturing, and superior electrical performance.

TI-Electronic SMT Assembly Services

🔹 SMT Panel Size: 01005 to 45mm x 45mm

🔹 Special Component Handling: BGA, µBGA, CSP, QFN, Flip Chips

🔹 Soldering Technologies: Lead-Free and Selective Soldering

🔹 Prototype and Mass Production: Flexible Manufacturing Options

📌 Do you need state-of-the-art SMT assembly? Trust the experts at TI-Electronic!

BGA – Reliable Ball Grid Array Soldering at TI-Electronic:

Ball Grid Array (BGA) is a special surface mount packaging technology that uses solder balls instead of traditional pins. This significantly improves electrical performance, heat dissipation, and mechanical stability.

BGA Assembly at TI-Electronic

✅ Precision Soldering Processes

✅ X-ray Inspection to Detect Defects

✅ BGA Reballing and Repair Services

✅ Lead-Free and RoHS Compliant Manufacturing

📢 If you need professional BGA assembly service, choose TI-Electronic!

THT – Through-Hole Technology at TI-Electronic:

Through-hole technology (THT) is a foundation of traditional electronics manufacturing, where component legs are placed in pre-drilled holes and soldered on both sides. This provides excellent mechanical stability and high temperature resistance.

TI-Electronic THT assembly services

🔹 Automated wave soldering and manual soldering

🔹 Precise placement of axial, radial and DIP components

🔹 Strong mechanical fixation for high-performance circuits

🔹 Prototype and mass production according to individual requirements

💡 Robust, long-lasting PCB assembly? Trust the experts at TI-Electronic!

Hand Assembly and Precision Soldering at TI-Electronic:

Manual PCB assembly is essential in projects where:

✔️ Custom or small series production is required

✔️ Special or sensitive components are being installed

✔️ Some components cannot be automated

TI-Electronic manual soldering solutions

✅ 30+ years of experience in precision soldering

✅ Manual placement and testing for small and medium series

✅ Waterproof and high IP-rated coatings (PCB varnishing)

✅ Functional testing and inspection on each piece

📌 Manual PCB assembly from expert hands? TI-Electronic is the best choice!

Protective Coatings and Lacquer Coatings at TI-Electronic:

PCB varnishing (conformal coating) is essential for the protection of circuit boards:

✔️ Protection against moisture and dust

✔️ Heat resistance and corrosion protection

✔️ Electrical insulation for longer life

TI-Electronic PCB coating solutions

🔹 Automated and manual coating

🔹 Acrylic, polyurethane and silicone-based coatings

🔹 UV and thermosetting coatings with fast drying

🔹 Unique masking options for sensitive components

📌 Maximum protection for PCBs? Trust the experts at TI-Electronic!