Ferrite and Nanocrystalline

TI-Electronic – Knowledge-based electronic manufacturing

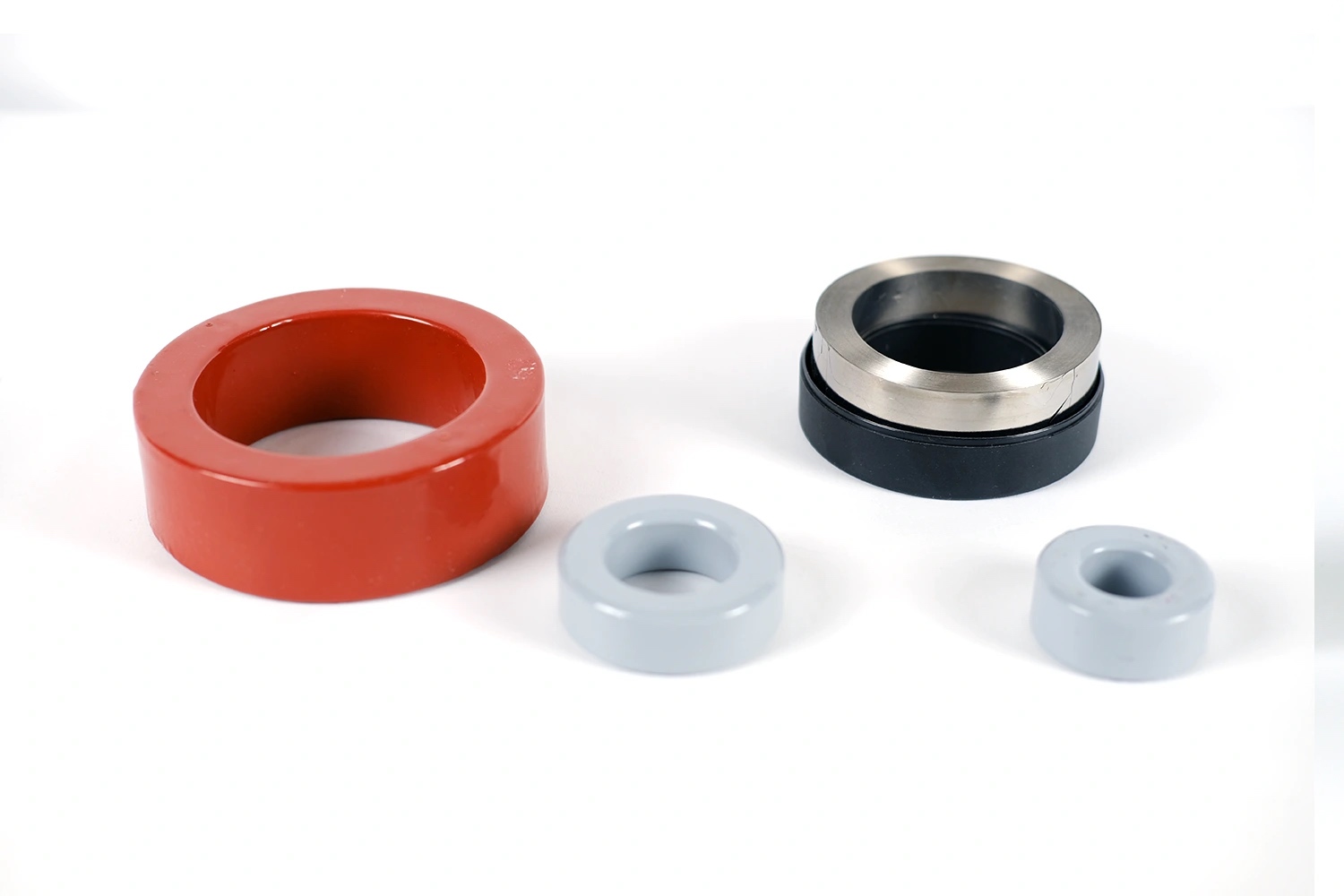

Expertise in Ferrite and Iron Powder Core Production

est.

1992

Decades of expertise

98,6

%

Satisfied customers

Since 1996, TI-Electronic has been a leader in the development and production of ferrite and powdered iron core products. With decades of experience in the industry, we offer a wide range of high-quality core products that are rigorously tested to meet industry standards.

Our partner in the development of cores is the Hungarian Central Physical Research Institute.

Our cores are widely used in various fields, including:

- Industrial electronics

- Broadcasting technology

- Lighting technology

- Automotive industry

Our inductor division manufactures and develops coils, transformers, and filters from these cores based on client needs. Our dedication to quality ensures that each product meets the specific requirements of its intended application.

You can download the detailed catalog of our ferrite and iron powder core products from our website. Additionally, we offer custom production and quality control for product types not listed in our catalog.

Nanocrystalline Material Cores

At TI-Electronic, we are also specialists in the production of cores made from nanocrystalline materials. These materials allow us to produce inductive elements that meet the ever-growing demands of frequency and operating temperature in modern electronics.

Key Features of Nanocrystalline Cores:

- High-frequency performance: Metal-metal type nanocomposites can be used up to 10 MHz, while metal-insulator nanocomposites operate up to GHz range frequencies.

- Versatile permeability: Through specialized heat treatment, the permeability of our nanocrystalline cores can be adjusted between 25,000 and 90,000, allowing for highly customizable applications.

- Wide application range: Our cores are suitable for switch-mode power supplies, current meters, and other electronic systems requiring low permeability and linear magnetization.

Currently, we focus on producing metal-metal nanocomposites, specifically nanocrystalline alloys. These alloys are made by heat-treating amorphous structures, which are produced by rapid cooling. We can produce amorphous tapes in widths between 4 and 20 mm, and larger cores are created by stacking thinner cores together.

Fe-based nanocrystalline material with composition of mostly Fe with Cu,Nb,Si,B, which first by rapid quenching technology to form amorphous ribbon, then by crystalline heat treatment to gain fine grains with nano scale. Through this revolutionary process, we can get superior magnetic properties with high saturation flux density, high initial permeability, low coercivity, low core loss. Nanocrystalline material is an environmental protection, green, low carbon,high efficiency new magnetic material.

Magnetic Properties Comparison: Amorphous and Nanocrystalline VS Traditional Soft Magnetic Materials:

Fe-Si Steel | Mn-Zn Ferrite | 80Ni Permalloy | Cobalt-based Amorphous | Fe-based Amorphous | Fe-based Nanocrystalline | |

Saturation Flux Density Bs(T) | 2.03 | 0.5 | 0.74 | 0.58 | 1.56 | 1.25 |

Coercivity Hc (A/m) | 40 | 8 | 2.4 | 0.4 | 2.4 | 1.2 |

Initial Permeability μi | 1500 | 3000 | 40000 | 100000 | 5000 | 80000 |

Max Permeability μm | 20000 | 6000 | 200000 | 1000000 | 50000 | 400000 |

Electrical Resistivity (μΩ .cm) | 50 | 5×107 | 60 | 140 | 130 | 115 |

Curie Temperature Tc(°C) | 750 | 220 | 450 | 250 | 399 | 570 |

Applications of Amorphous and Nanocrystalline Cores:

Application | Fe-based Amorphous | Co-based Amorphous | Fe-based Nanocrystalline |

EMC, EMI, EMC Common Mode Choke, EMI Filter | √ | ||

Current Transformer | √ | √ | |

High Frequency Transformer | √ | ||

Magnetic Amplifier | √ | √ | |

Network transformer, driver transformer | √ | √ | |

Solar Inverter Reactor | √ | ||

Car Audio output inductor | √ | ||

PFC, PFC choke, Out filter inductor | √ | √ |